12V Powernet

Battery Management

Eatron’s highly reliable 12V Powernet Battery Management System is an enabling technology for increased electrification and autonomy.

Industry 12V

Challenges

Built on automotive experience, and our advanced Battery Optimisation Software, be certain in your battery performance, safety and lifetime.

Functional

Safety

Ensuring the vehicle’s functional safety and ever increasing automated driving features, 12V BMS provides reliable power deliverability at all times.

Lifetime

Prediction

Accurately tracks battery degradation and predicts necessary battery replacement to maintain uncompromised vehicle functionality.

Exceptional

Reliability

Operating constantly to supply quiescent current means the HW is developed with best-in-class components for reliability and ultra low power consumption.

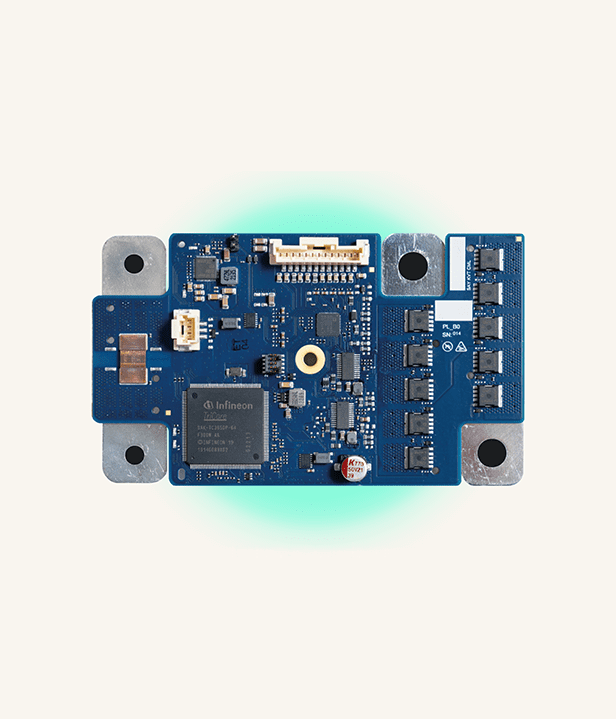

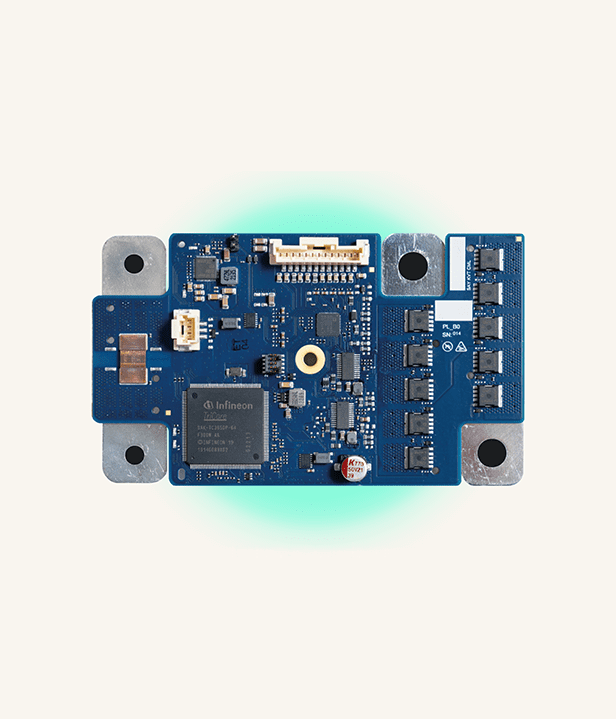

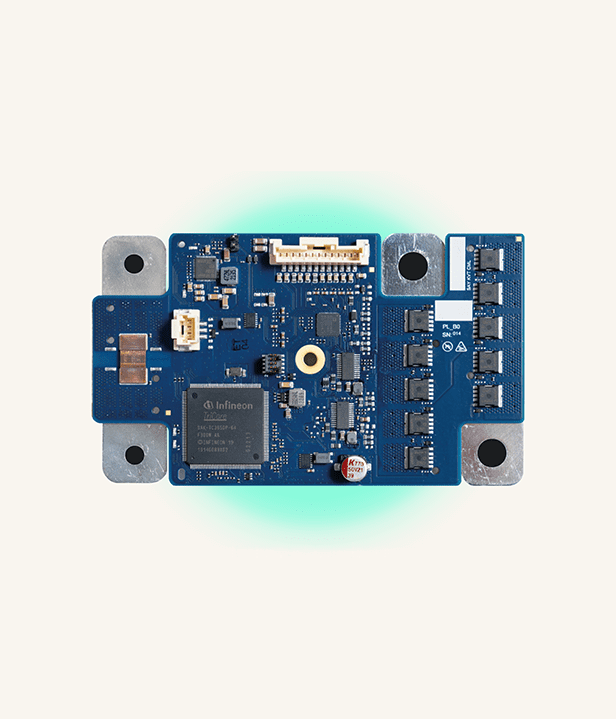

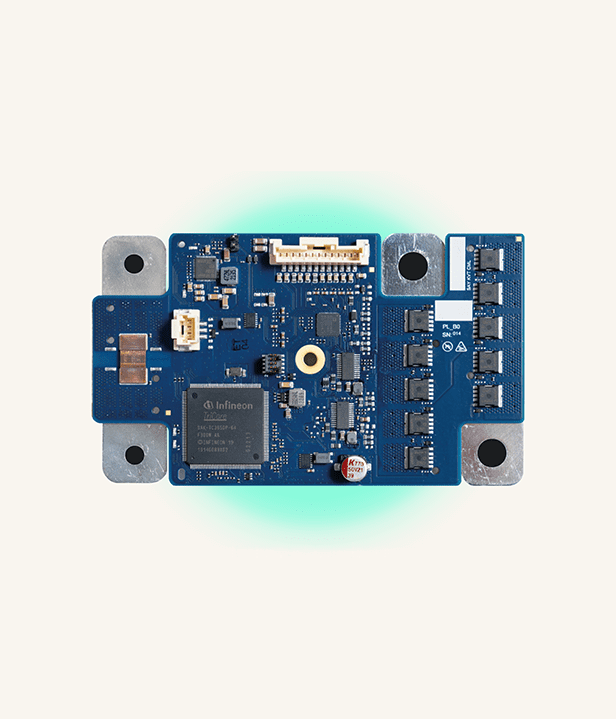

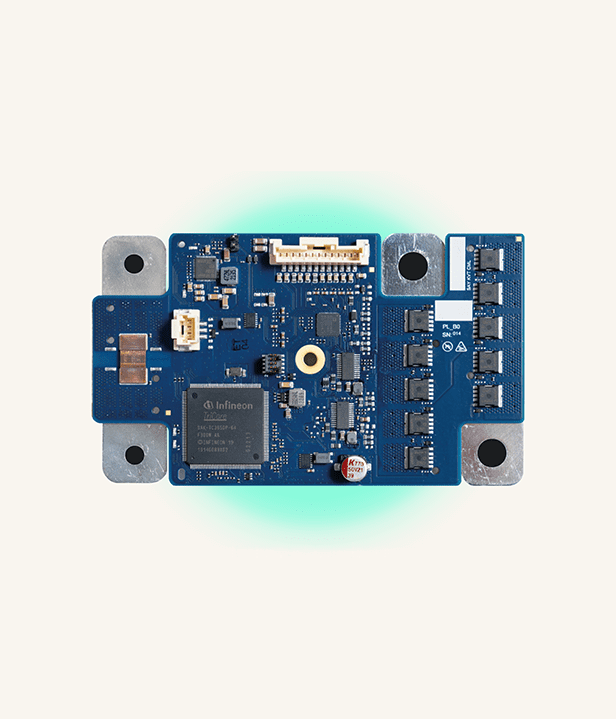

12V BMS

Hardware Features

-

High power capability

Delivering 200A continuously at 65°C ambient thanks to high performing MOSFET technology, which also supports crank pulses and short circuit currents of over 1400A for 1s.

Integrated dual bank circuit breaker concept allows diagnosis of circuit breaker operation and faults without interrupting supply of quiescent power to the vehicle Powernet. -

Advanced battery protection

The battery is protected from safety hazards at all times including the sleep mode.

A dedicated short circuit protection safeguards against common short faults across the terminals.

Reverse polarity protection ensures robustness against accidently mixing the terminals during jump start event. -

Accurate current measurement

Allows for accurate current measurement across a wide range of current and temperature. This includes accurate quiescent current monitoring during sleep mode.

-

Highly optimised reliable design

Design optimised for cost, high volume manufacturing and 15-year in service requirements.

Self-current consumption of 250uA when the vehicle is parked, meeting strict targets for applications without wake-up to charge feature. -

Best in-class chipset

Powered by Aurix TC365 – providing required performance, safety and connectivity (LIN of CAN FD) features.

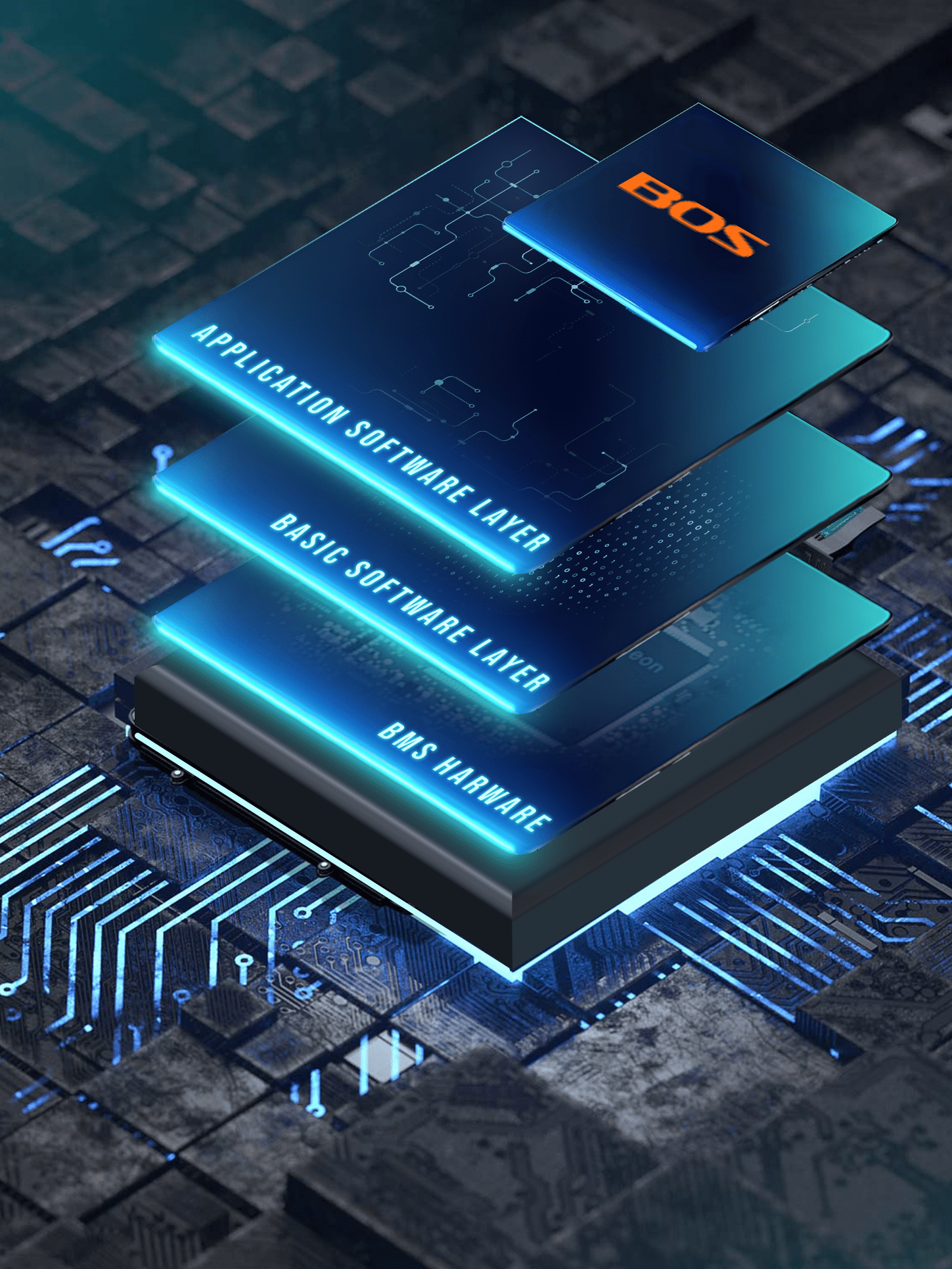

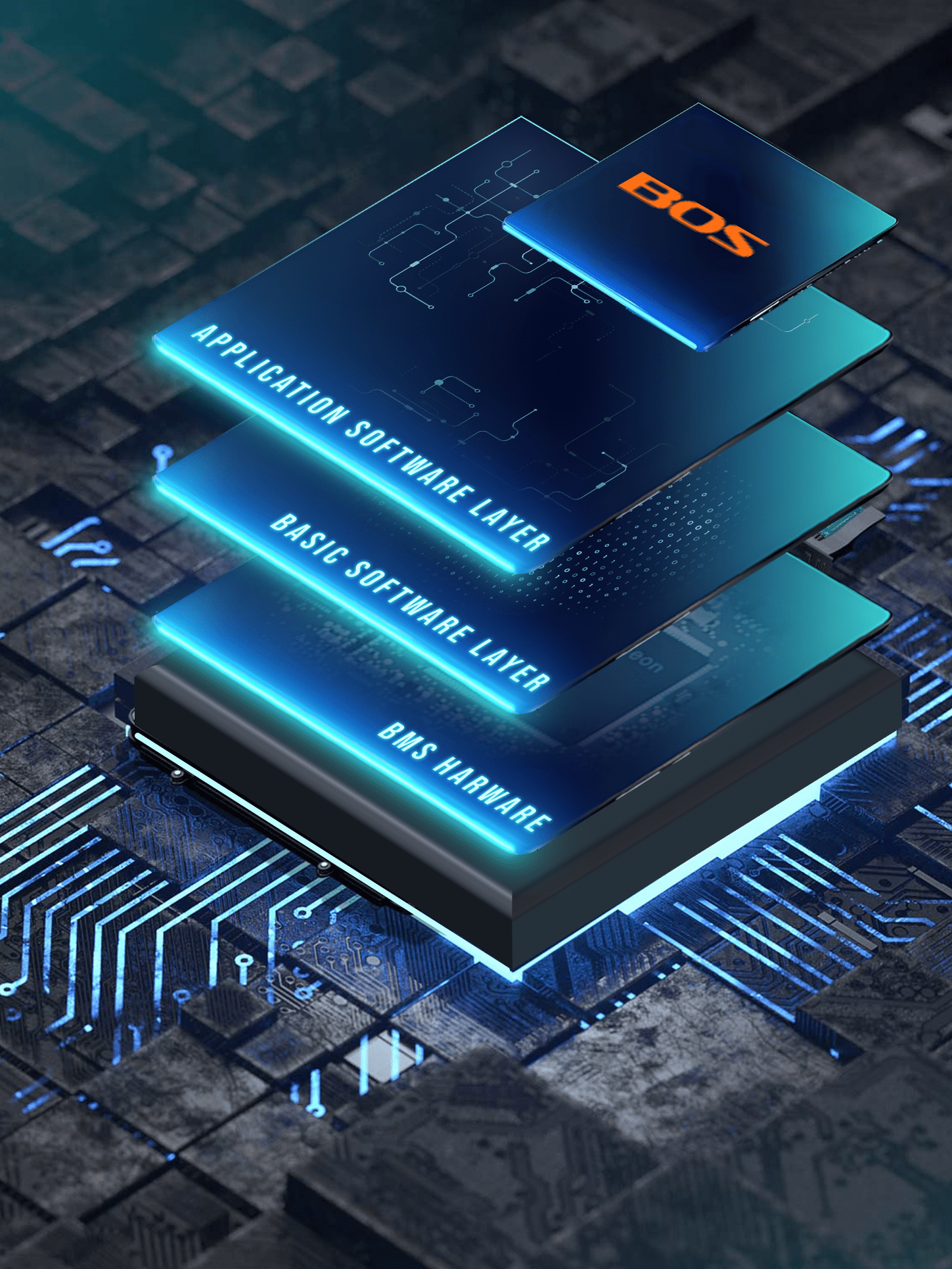

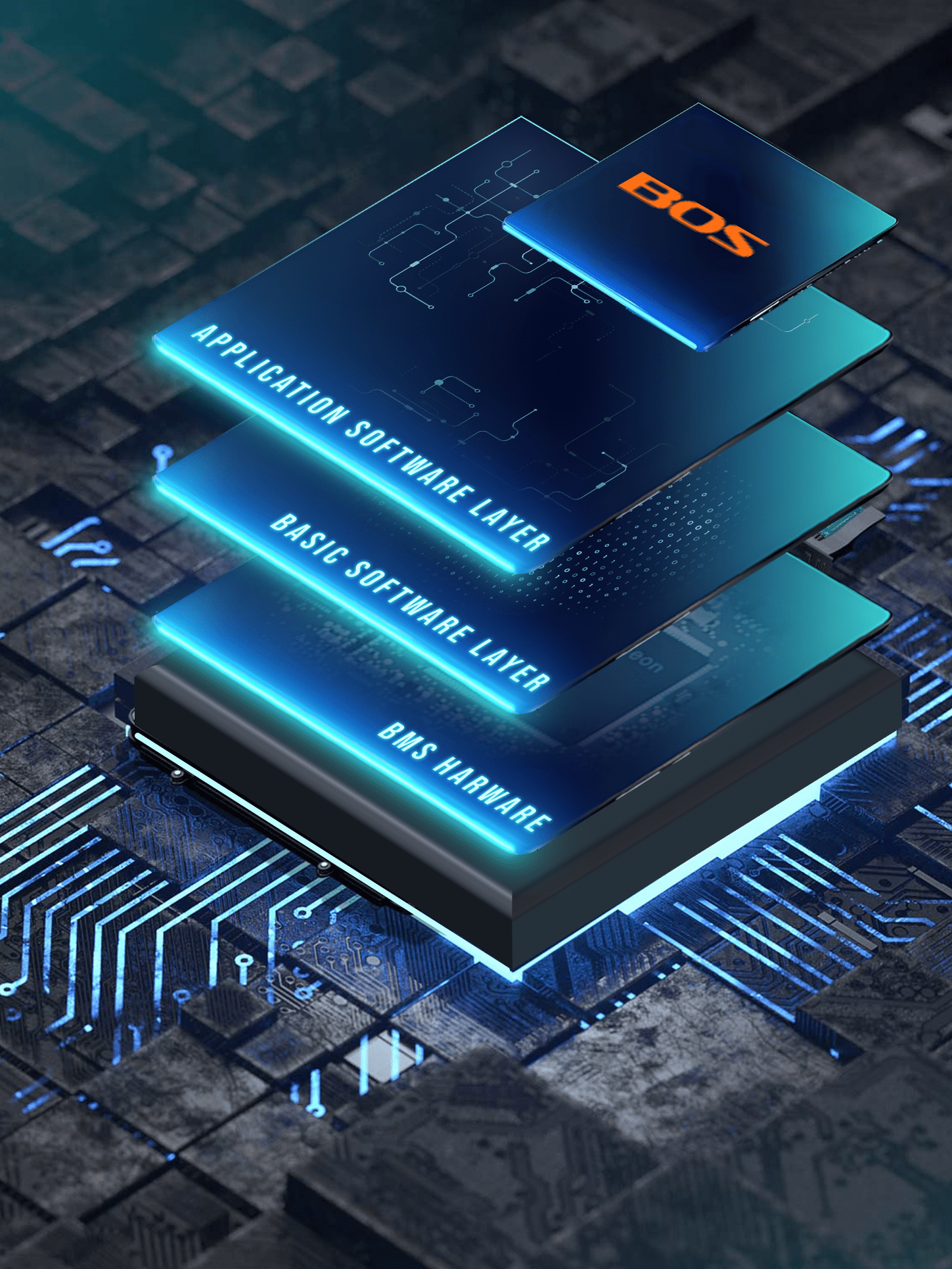

12V BMS

Software Features

-

Advanced state estimation and balancing

Accurately estimates the State of Charge and State of Health of the battery, supporting both LFP and NMC chemistries.

It also ensures all battery cells remain well balanced. -

Power pulse prediction

Provides accurate information about battery’s ability to provide power to complete a specific ‘mission profile’, e.g. automated driving or parking, in case of failure of the main power source, e.g. DCDC converter.

-

Battery protection

Ensures the battery is always protected from all safety hazards in all operating modes.

It controls circuit breakers independently in charging and discharging direction including highly robust diagnostics of all possible failures. -

Monitoring quiescent current

Monitors Powernet quiescent current and notifies vehicle’s energy management system about any abnormalities that could lead to excessive battery drain.

-

Service and maintenance support

The BMS records key field usage and diagnostics data for offline analysis.

It supports over-the-air software update with A/B image swap concept.

Book a Demo

Discover how our solutions can transform your operations.

How to

work with us

Book a Call

Let us understand your specific requirements to determine the fit of our 12V BMS platform solution.

Initial Evaluation

We will help you integrate our 12V BMS platform into your battery and calibrate it to your specific cell, so you can carry out necessary evaluation. If needed the mechanical concept can be adjusted at this stage.

Production Development

We will carry out all the necessary HW and SW modifications to meet all of our requirements, and mature the design for you through the DV, PV and PPAP stages. Before going into production, the 12V BMS will be assessed in accordance to ASPICE and ISO26262.

Field Updates

Post-production we can continue to support you with software improvements OTA.

FAQs

Find answers to your questions about our company and services in this FAQ section.

Being a small and agile company gives us an advantage to operate effectively under lean development processes. We combine over 150 years of automotive and battery management system development experience and we know how to get it right. Our passion for technology helps us leverage all the advanced automations tools to bring the product to market fast.

Quality is in our DNA and we continue to push ourselves and our products to adhere to strict automotive standards like ASPICE, Functional Safety (ISO26262), Cybersecurity (ISO21434) and ISO9001. We also know that our customers wouldn’t expect anything less of us.

We believe that the future of electronics manufacturing is to deploy the Electronics Manufacturing Services (EMS) model. This gives a small and flexible company like Eatron an advantage to capitalise on our expertise to produce a world class design, whilst leaning on the reliable and cost effective partner to do the manufacturing.

Get in Touch

We’re here to assist you with any inquiries.