Complete

Peace of Mind

Proactively protect batteries using Eatron’s BOS with intelligent, real-time diagnostics that detect risks before they escalate.

Industry Safety

Challenges

Our software suite integrates seamlessly at the edge or

in the cloud – turning data into intelligence and giving

you the edge in electrification.

Thermal Runaway Events

Around 30% of EV recalls stem from battery safety issues, with runaway reactions causing fires or explosions.

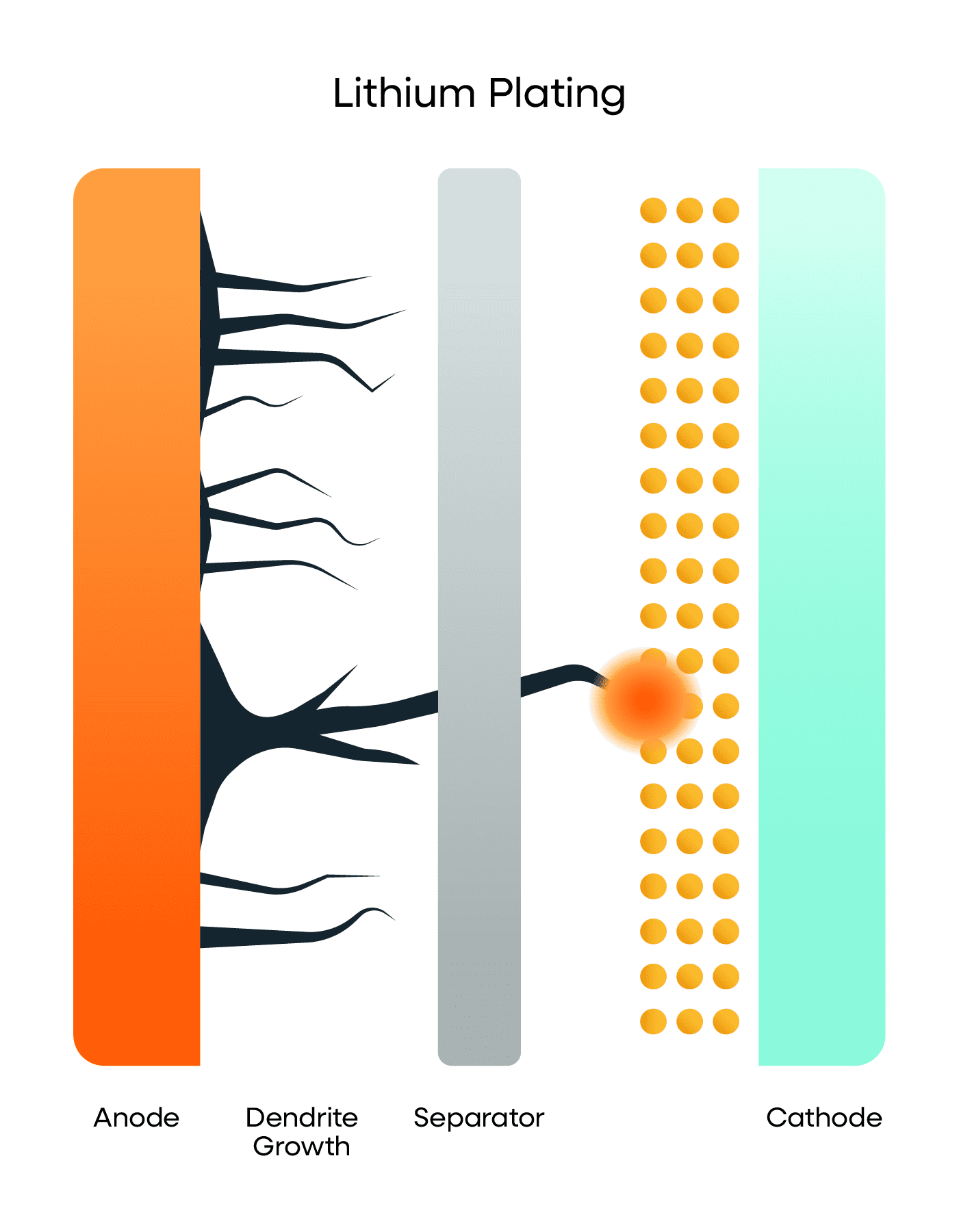

Hidden Cell Anomalies

Failures like lithium plating or self-discharge often go undetected – until performance or safety is compromised.

Costly Recall Fallout

Safety-related incidents can trigger multi-million-dollar recalls and erode customer trust overnight.

Our Safety

Software Features

-

Lithium Plating Detection

AI-powered models detect early signs of lithium plating – reducing the risk of thermal runaway and protecting battery capacity over time.

-

Anomaly Detection

Identifies unusual cell behaviours such as self-discharge, capacity fade, or resistance growth before they turn into critical failures.

-

Thermal Runaway Prediction

Combines supervised and unsupervised AI to forecast thermal events in real-time, enhancing safety and reliability at both pack and cell level.

-

Seamless BMS + Cloud Integration

Seamless BMS + Cloud Integration

Deployment Options

-

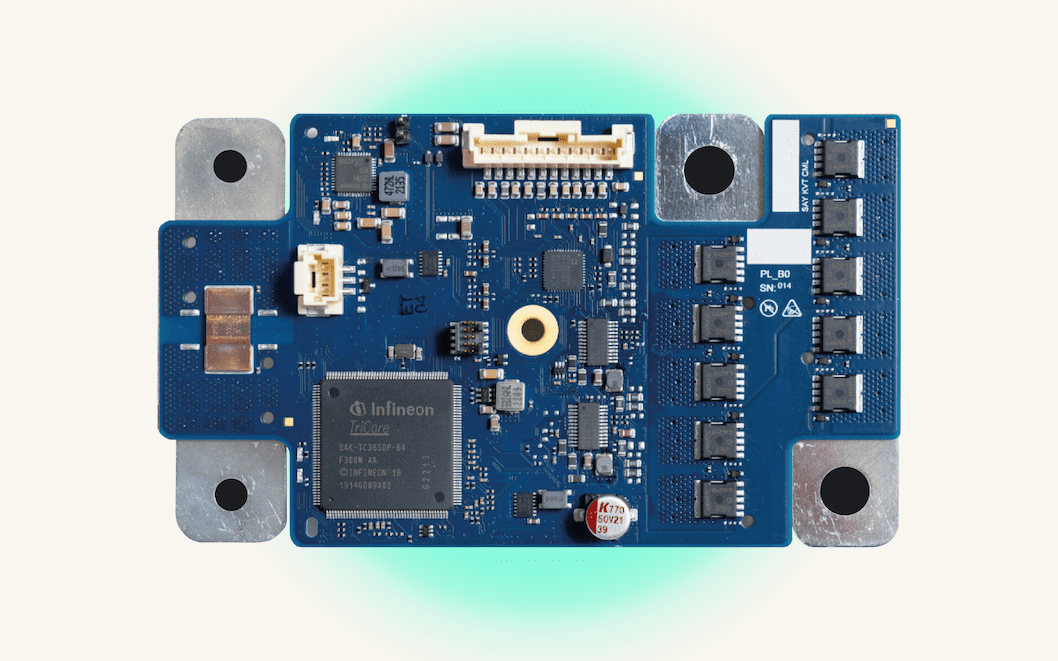

Edge Deployment

Deploy directly to BMS microcontrollers (e.g., Infineon, Renesas) for the low latency, high frequency compute needed for decision making at the edge.

-

Cloud Deployment

Run models in a cloud environment – either customer-hosted or in Eatron’s cloud – with secure API access for data integration and fleet-wide monitoring.

-

Flexible Delivery

Choose from compiled binaries, standalone models, or HW integrated on-chip solutions, tailored to your platform architecture and compute constraints.

Book a Demo

Discover how our solutions can transform your operations.

How to

work with us

Talk to an Expert

Identify safety challenges and learn how our predictive models can support early detection.

Try it Out

Validate anomaly detection and lithium plating models on your battery configuration.

Go Live

Deploy real-time safety diagnostics into your BMS or cloud environment.

FAQs

Find answers to your questions about our company and services in this FAQ section.

No. Our models run efficiently on standard BMS hardware without requiring additional sensors or specialised processors.

Our pre-trained models work out-of-the-box and improve rapidly using transfer learning. We don’t require exhaustive datasets – just representative samples.

Our models are built with battery-specific feature engineering and include uncertainty estimation, offering results that are explainable and trustworthy.

We can detect failure modes that lead to thermal runaway weeks in advance, enabling proactive safety interventions.

Yes. We’ve validated our models across LFP and NMC chemistries with consistent results.

Get in Touch

We’re here to assist you with any inquiries.