Why is the cloud important?

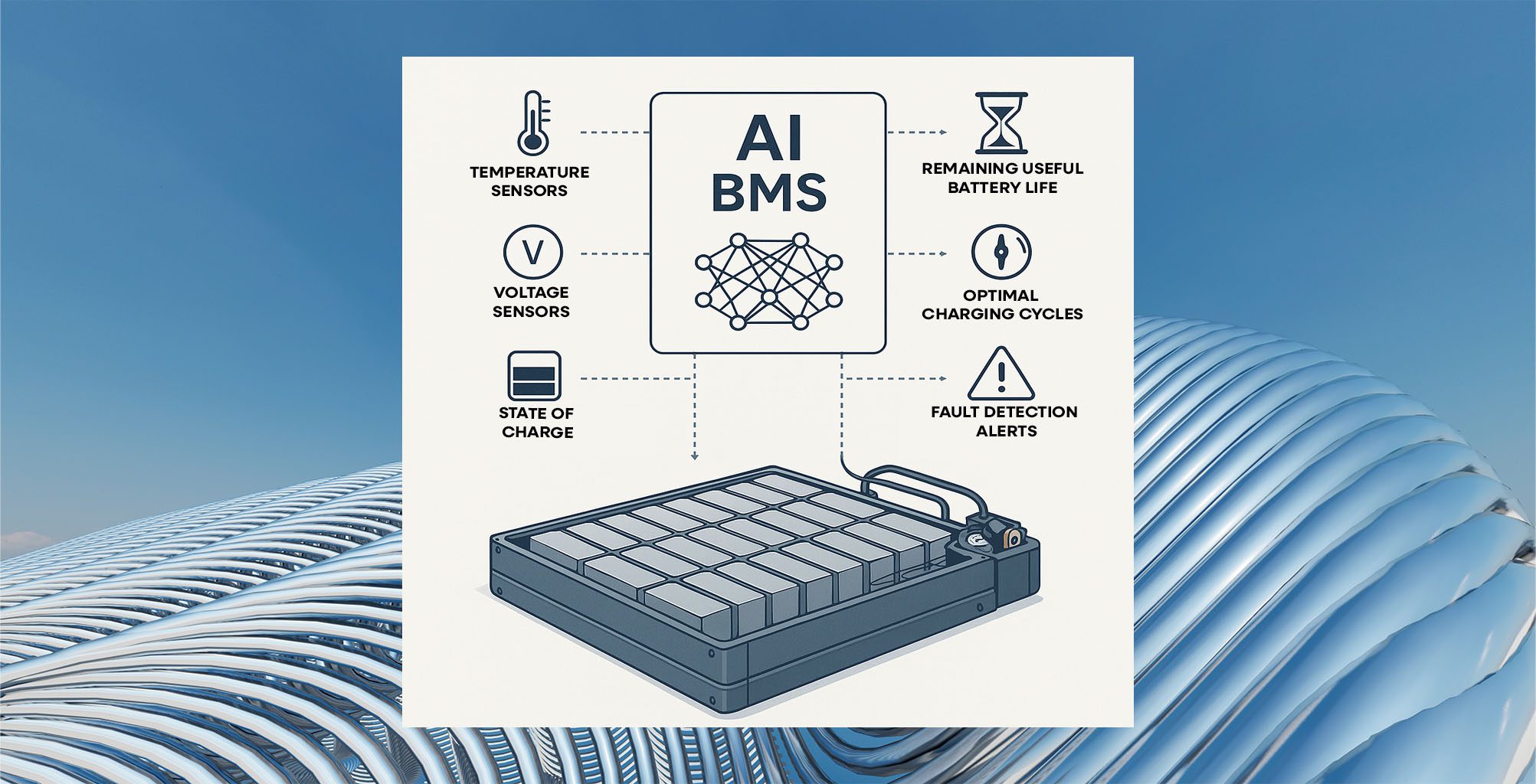

By embracing the cloud, the automotive industry is unlocking the potential to analyse limitless amounts of data faster and more comprehensively than ever. Notably, its use can play a key role in the operation of highly intelligent battery management systems that are vital to ensuring good and safe performance of electric vehicles.

Why is the cloud important?

The cloud is nothing new, but its relatively recent adoption by the automotive industry paves the way for future advances in vehicle technology. And it’s battery management systems that stand to gain significantly.

Although we often think of the cloud as a new invention, it’s been with us for decades. The name itself hails from the cloud symbol used to depict the internet on flowchart diagrams of old, and today it’s come to symbolise the use of services hosted somewhere in the ether.

But why has the cloud become so important to the automotive industry?

“As our lives have become increasingly connected, we’ve grown used to storing more of our data in the cloud,” explains Ibrahim Halatci, Eatron Technologies’ Head of Engineering. “Customers expect to be able to access their music whether they’re at home or on the move, and the rise of the connected car has enabled that. However, the value to the automotive industry is far greater, and it all has to do with big data.”

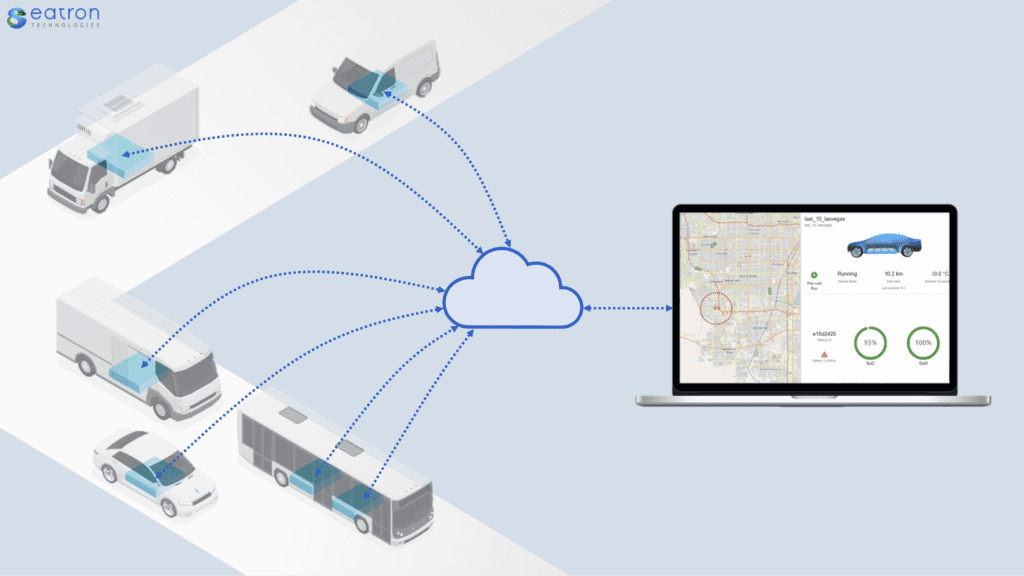

Modern cars are increasingly defined by software. Each system – be it the battery, traction motor, the brakes, or even the ventilation system – is part of a network of devices within the vehicle that are in constant communication with each other. Each device is continually measuring and optimising its own performance, and over time this generates vast quantities of data.

Traditionally, this data would be analysed locally, at the edge of the device, where it interfaces with the rest of the vehicle. But this approach requires each device to be equipped with sufficient computing horsepower to perform this analysis by itself, not to mention the storage capacity to hold it all. That can quickly become cost prohibitive, and with some devices generating gigabytes of data every day, it may even be entirely impractical.

By contrast, the cloud has limitless resources, both in terms of storage and computing power. Adding capacity to a datacentre is relatively cheap. And while the computing power of a connected car is fixed the moment it leaves the factory, the cloud it is connected to can be easily scaled up as time moves on.

“The amount of data produced by an intelligent vehicle is estimated to be several hundreds of gigabytes, generated by hundreds of sensors and thousands of parameters in the edge software. This is huge,” says Halatci. “However, it should also be noted that limitless cloud does not necessarily mean transmitting all this data for processing. Instead, the focus should be more on the computational power to estimate and calculate the states of the battery. AI–based and physics-based models (‘Digital Twins’) are the algorithms developed to run with the carefully selected and bandwidth –optimized sensor measurements.”

The connected nature of today’s cars means they are already equipped with everything necessary to transmit this data to the cloud, where it can be processed and analysed anonymously. Security and privacy considerations are central to Eatron’s safe approach, and none of the data used contains personally identifiable information.

But the real value of the cloud comes in being able to analyse data from multiple sources, and potentially thousands of vehicles. Having access to a large dataset makes it much easier to spot trends and discover commonalities, perhaps helping to identify failures before they happen to improve safety, or establish ways of improving efficiency. This is particularly critical for fleet owners and operators to monitor so that they may proactively take actions to maximize the uptime of their fleet.

“The cloud allows us to close the loop,” says Halatci. “For example, traditional battery management systems (BMS) are fixed at the point of design, and stay that way throughout the life of the vehicle. But with the cloud, we can improve it over time, using insights gained from our analysis to deploy updates to the vehicle that learn not just from that user, but many thousands of users. With more data points available to us, it increases the confidence in our analysis, too.”

Analysing data from multiple users also allows Eatron to understand the effects of different driving styles and usage profiles on the battery, and this can lead to new and improved management techniques that increase range or significantly extend the life of the battery.

Here, Eatron’s work on developing Remaining Useful Life (RUL) estimates could give a used vehicle buyer an accurate and reassuring picture of battery health, helping to ease what is often cited as a barrier to EV ownership.

“Without the cloud, this level of analysis just wouldn’t be possible,” concludes Halatci. “Now we can harness the power available not just at the edge of one device, but across a whole fleet.”

Ibrahim Halatci, CCO at Eatron Technologies.

At Eatron we develop intelligent Battery Management Software solutions that can be deployed on both the edge and the cloud. If you are interested in learning more about these click on ‘Talk to an Expert’ and fill in the contact form or email info@eatron.com.